Top Causes of Commercial Roof Leaks—and How to Prevent Them

December 4, 2025 4:20 pm Leave your thoughtsCommercial roof leaks are more than just a nuisance; they can be a costly disruption to business operations, damaging inventory, creating safety hazards, and increasing maintenance costs. Preventing these leaks begins with understanding their root causes. Commercial roofing problems often develop slowly over time, making early detection and consistent upkeep critical to prolonging the life of your building’s roofing system. In this post, we explore the most common causes of commercial roof leaks and offer practical guidance on how to prevent them, saving your business from unnecessary expenses and operational interruptions.

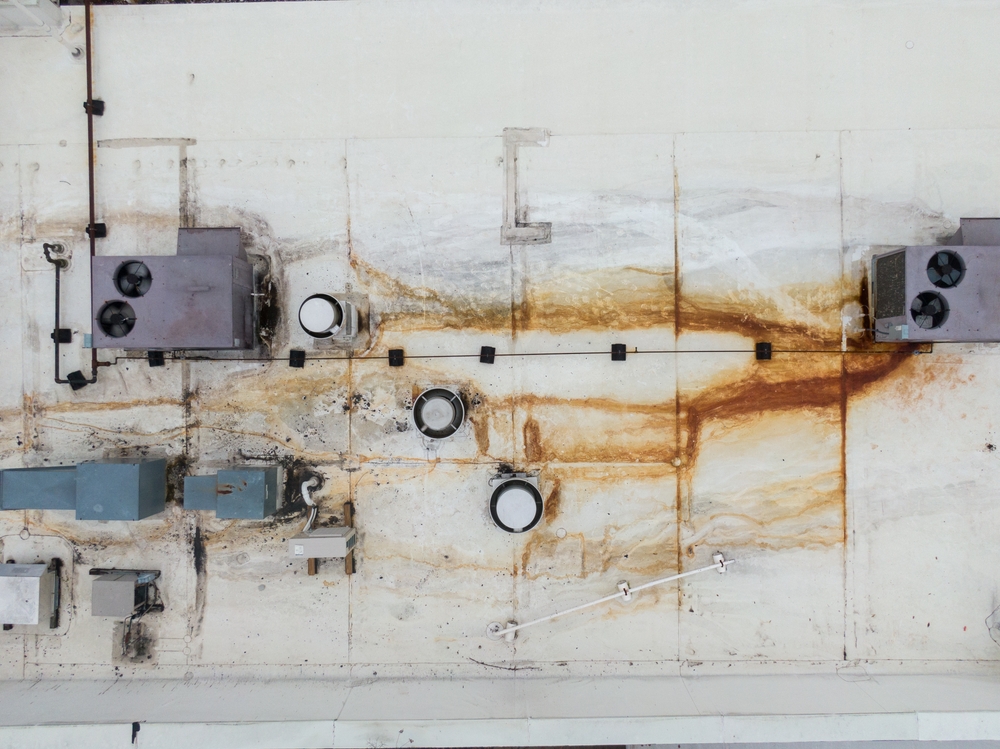

Poor Drainage and Ponding Water

One of the leading causes of commercial roof leaks is poor drainage, especially on flat or low-slope roofs. Unlike pitched residential roofs that naturally shed water, commercial roofs often require a carefully designed drainage system to move water away efficiently. When drains or scuppers become clogged with debris, such as leaves, dirt, or industrial waste, water begins to pool. Over time, this ponding water places added stress on the roof membrane, increasing the risk of cracks, leaks, and structural damage.

If water remains stagnant for extended periods, it can break down roofing materials, promote algae and mold growth, and eventually seep through the smallest weaknesses in the surface. This is particularly dangerous because damage may be occurring beneath the membrane, going unnoticed until leaks appear inside the building.

To prevent this, regular inspection and cleaning of all roof drainage components is essential. Facility managers should schedule monthly cleanings, especially during fall and spring when debris accumulation is common. Additionally, installing more drains or adjusting slopes to improve water runoff can offer long-term benefits. Monitoring for signs of ponding water after storms is a quick way to identify areas that may need adjustment or repair.

Damaged or Aged Roofing Materials

Commercial roofing materials are built to endure significant wear and tear, but they are not immune to the passage of time. As roofing systems age, materials like EPDM rubber, TPO, PVC, and modified bitumen naturally begin to degrade. UV exposure, fluctuating temperatures, and weather extremes contribute to the gradual weakening of the roofing membrane. Cracks, blisters, and tears become more likely, and seams that were once tightly sealed can start to separate.

This degradation is often accelerated by environmental conditions such as high winds, heavy rain, or hail. Roofing materials can shrink or expand with temperature changes, leading to stress fractures and openings where water can enter. In some cases, improper installation or low-quality materials can significantly shorten the roof’s lifespan, leaving the building vulnerable to leaks sooner than expected.

The best prevention strategy is to invest in a high-quality roofing system from the outset and ensure it is installed by certified professionals. Once installed, proactive maintenance is key. Roofs should be inspected at least twice a year, ideally in the spring and fall, and after major weather events. Any minor issues, such as loose seams or small punctures, should be repaired promptly to avoid more extensive damage down the line.

Flashing Failures and Penetration Points

Flashing is used to seal the edges of commercial roofing systems, particularly where the roof meets walls, vents, HVAC units, and other penetrations. These areas are among the most vulnerable points in any commercial roofing system, as they involve transitions in materials and structures. When flashing becomes loose, cracked, or improperly sealed, water can quickly find its way inside.

Common causes of flashing failure include aging, poor installation, temperature-induced expansion and contraction, or physical damage. Even the best roofing membranes can become compromised if the flashing isn’t performing its role. Leaks that originate at penetration points may go undetected for a while, especially if they occur beneath rooftop units or along parapet walls.

Preventing commercial roof leaks caused by flashing begins with using high-quality flashing materials and ensuring expert installation. It’s important to regularly inspect these areas and reseal or replace flashing that shows signs of wear. Technicians should also examine areas around skylights, chimneys, and rooftop units, which are frequent trouble spots. Applying protective coatings and reinforcing vulnerable joints with advanced sealing products can add another layer of protection.

Improper Roof Design or Installation

A well-designed commercial roof takes into account slope, drainage, building movement, and climate conditions. When these factors are overlooked or poorly executed, the likelihood of roof leaks increases significantly. A common commercial roofing problem is inadequate slope, which results in poor drainage and water accumulation. Additionally, improper installation of insulation, membranes, or flashing can leave gaps that allow moisture intrusion.

Design flaws may also involve insufficient ventilation or thermal expansion planning. Buildings shift and settle over time, and if the roof system isn’t designed to accommodate these movements, materials may crack or separate. Poor workmanship, such as uneven application of roofing materials or failure to adhere to manufacturer guidelines, is another frequent contributor to premature roof leaks.

The best way to avoid these issues is by partnering with experienced commercial roofing contractors who understand both design and installation best practices. Before any work begins, it’s vital to conduct a comprehensive assessment of the building’s needs, local weather patterns, and future growth projections. During installation, quality assurance measures and third-party inspections can help catch errors before they lead to leaks. Once installed, a tailored maintenance plan will keep the roof performing as designed for decades.

Lack of Preventive Maintenance

While commercial roofing systems are engineered for durability, they still require regular maintenance to perform at their best. Many leaks occur not because of catastrophic failure, but due to small, undetected issues that worsen over time. Loose fasteners, minor membrane tears, and blocked drains are easy to fix when caught early but can cause serious problems if neglected.

In busy commercial environments, roof maintenance is often overlooked until a leak is discovered. By that point, water may have already damaged insulation, ceiling tiles, or electrical systems, leading to expensive repairs and potential safety hazards. Neglecting routine maintenance also shortens the lifespan of the roof, ultimately increasing replacement costs.

Implementing a proactive maintenance plan is the most effective way to prevent commercial roofing problems. This includes scheduled inspections, seasonal cleaning, and prompt repair of any damage. It’s also wise to keep detailed records of maintenance activities and inspection reports. This documentation not only helps track the roof’s condition over time but can also be valuable for warranty claims or insurance assessments.

Conclusion

Commercial roof leaks are a serious concern for building owners and managers, but they are not inevitable. Understanding the top causes, from poor drainage and aging materials to flashing failures and design flaws, empowers stakeholders to take preventive action. The most common commercial roofing problems often stem from a combination of factors, which is why a comprehensive approach to maintenance and care is essential.

Regular inspections, quality materials, skilled installation, and proactive upkeep can dramatically reduce the risk of leaks. By addressing small problems early and maintaining a strong roof management plan, businesses can protect their assets, avoid costly repairs, and extend the life of their commercial roofing systems. Investing in your roof’s longevity isn’t just about avoiding leaks; it’s about ensuring the long-term success and safety of your operations.

Need a Roofing Company in Springfield, MA?

Since 1987, R & H Roofing has remained one of the most trusted names in the roofing industry. We specialize in commercial and industrial roofing and offer a wide variety of roofing systems including EPDM systems, TPO Systems, Metal Roofing Systems, BUR Tar & Gravel Systems, Asphalt Shingles, and PVC Systems. We also work with some of the leading manufacturers including Firestone, Carlisle, Duro-last, and Garland. Contact us today to learn more about what we can do for you!

Categorised in: Commercial Roof Repair, Commercial Roofing

This post was written by admin