How Industrial Roofing Materials Compare: EPDM, PVC, Metal, and Built-Up Roofs in Western MA

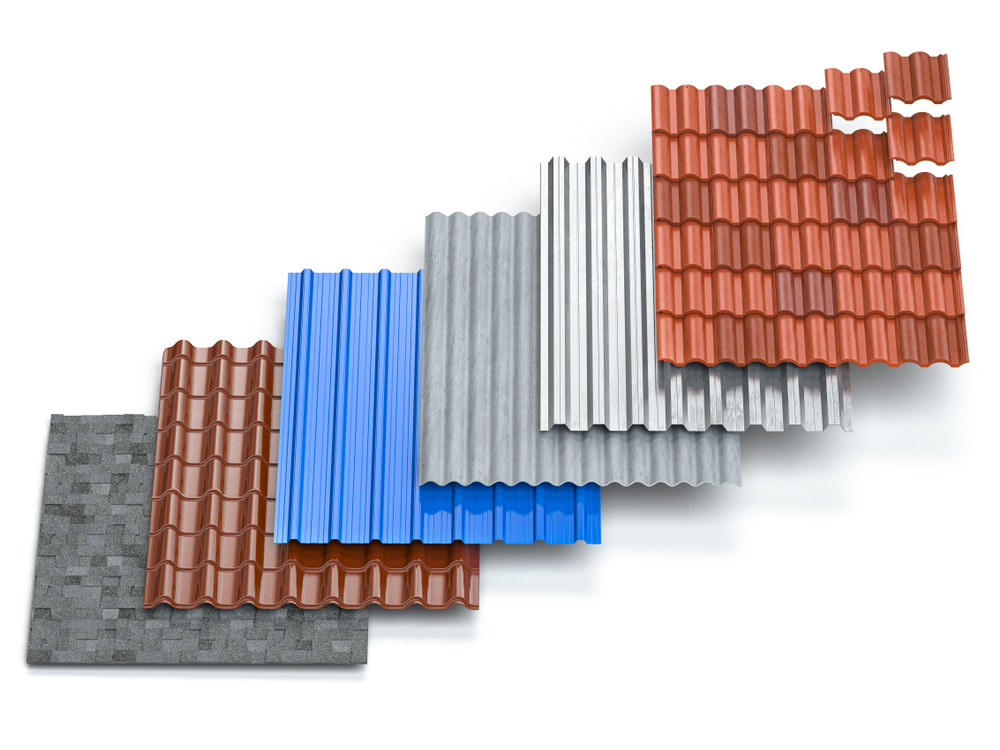

January 1, 2026 7:54 pm Leave your thoughtsChoosing the right industrial roofing materials is a critical decision for property owners and facility managers in Western Massachusetts. The climate, with its heavy snowfall, seasonal rains, and temperature fluctuations, places unique demands on roofing systems. Whether you are planning a new build or replacing an existing structure, it’s important to understand how materials like EPDM, PVC, metal, and built-up roofing perform in this region. Each option brings its own set of advantages and challenges, and the right choice often depends on your building’s specific needs, budget, and long-term maintenance considerations.

A reliable roofing contractor in Easthampton, MA, can help guide the process, but having a foundational understanding empowers you to make informed decisions. From energy efficiency to resistance against harsh weather, this comprehensive comparison highlights what each material has to offer and where it excels.

EPDM vs PVC Roofing: A Close Comparison

EPDM (ethylene propylene diene terpolymer) and PVC (polyvinyl chloride) are two of the most widely used single-ply membranes in industrial roofing applications. Both are lightweight, flexible, and known for their durability, but they diverge in key areas that can make one more suitable than the other for your facility in Western MA.

EPDM is a synthetic rubber membrane that performs exceptionally well in cold climates. Its elasticity helps it resist cracking during freeze-thaw cycles, a valuable feature in Massachusetts winters. The dark color of traditional EPDM can also absorb heat, which may help melt snow and ice more quickly. However, that same trait can increase cooling costs in the summer. White EPDM variants exist to mitigate this effect, although they are less common.

PVC roofing, on the other hand, offers superior resistance to chemicals, oils, and grease, making it an ideal choice for buildings such as factories, restaurants, or manufacturing facilities. It is also naturally reflective, helping reduce heat gain during warmer months. This makes PVC a more energy-efficient option during Massachusetts summers. While both materials are easy to install and maintain, PVC tends to be more puncture-resistant but is generally costlier than EPDM. For professional industrial roof installation, the complexity of the structure and potential chemical exposure will often dictate whether EPDM or PVC is the better fit.

The Durability and Versatility of Metal Roof Systems

Metal roof systems are known for their exceptional longevity and structural strength. In Western MA, where buildings must withstand snow loads and fluctuating temperatures, metal roofing offers a dependable solution. These roofs can last anywhere from 40 to 70 years with proper maintenance, making them one of the most cost-effective long-term options in the industrial roofing market.

Made from materials such as steel, aluminum, or zinc, metal roofs are highly resistant to fire, mildew, pests, and rot. Their interlocking panel design allows for efficient snow shedding, which is particularly important in avoiding ice damming and associated water damage. Moreover, modern coatings and finishes have drastically improved metal’s resistance to corrosion and its thermal performance.

One notable advantage of metal roof systems is their compatibility with solar panels and other green technologies. In a region where sustainability is becoming increasingly important, choosing metal can support environmental goals while reducing energy expenses. A trusted roofing contractor in Easthampton, MA, can ensure these systems are installed with precision, sealing vulnerable areas and securing seams against moisture intrusion.

Built-Up Roofing Benefits in Harsh Northeastern Climates

Built-up roofing (BUR), also known as tar and gravel roofing, has been a staple of industrial roofing for over a century. Known for its proven performance, BUR systems are composed of alternating layers of bitumen and reinforcing fabrics. These layers are finished with a top coating of gravel or a reflective cap sheet, adding both protection and durability.

One of the primary built-up roofing benefits is its exceptional waterproofing capabilities. The multiple plies provide redundancy, which is particularly valuable in Massachusetts, where snowmelt and rain can lead to ponding water on flat roofs. BUR systems also offer impressive fire resistance and impact protection. This makes them ideal for industrial buildings that experience high foot traffic on the roof or that house critical equipment underneath.

Though BUR installations are typically more labor-intensive than single-ply membranes, their lifespan can exceed 30 years with proper upkeep. They also provide excellent insulation, reducing the need for additional thermal layers and improving energy efficiency during winter. Professional industrial roof installation is key to getting the most out of BUR systems. An experienced contractor will ensure proper drainage and adherence to building codes, which is vital in areas with strict weather-related regulations like Western MA.

Selecting the Right Material for Your Western MA Facility

Deciding among EPDM, PVC, metal, or built-up roofing ultimately depends on several critical factors including budget, facility usage, environmental concerns, and long-term performance expectations. For instance, a warehouse with limited exposure to chemicals may benefit from the affordability and cold-weather performance of EPDM. Conversely, a facility that handles oils or acids would be better served by the chemical resistance of PVC roofing.

Metal roofing is often chosen for buildings where structural integrity and longevity are paramount. It’s also a good fit for owners interested in renewable energy upgrades. Built-up roofing, while more traditional, continues to be a reliable option for facilities with flat or low-slope roofs requiring maximum waterproofing and protection against mechanical damage.

Working with a qualified roofing contractor in Easthampton, MA, ensures your chosen material is not only well-suited to the building but also installed to withstand the region’s unique weather patterns. Professional industrial roof installation can make or break the performance of even the highest-quality materials. Contractors familiar with local building codes and seasonal challenges bring an added layer of assurance to your investment.

Conclusion

Navigating the wide range of industrial roofing materials can feel overwhelming, but understanding the characteristics of each system helps narrow the choices significantly. EPDM and PVC offer lightweight, flexible options with strong performance metrics tailored to specific conditions. Metal roofs deliver unmatched durability and eco-friendliness, while built-up systems remain a time-tested solution for water resistance and longevity.

Western Massachusetts presents specific environmental challenges that demand careful consideration when selecting a roofing system. With the right approach and guidance from a knowledgeable roofing contractor in Easthampton, MA, your industrial facility can benefit from a roof that not only protects but also enhances the building’s value and efficiency.

Choosing the right material is just the beginning. Ensuring a professional industrial roof installation tailored to your site’s needs is the most critical step in safeguarding your investment for decades to come. Whether you’re evaluating EPDM vs PVC roofing, considering the benefits of metal roof systems, or exploring the built-up roofing benefits, a strategic approach backed by expert support will lead to long-term success.

Need a Roofing Company in Springfield, MA?

Since 1987, R & H Roofing has remained one of the most trusted names in the roofing industry. We specialize in commercial and industrial roofing and offer a wide variety of roofing systems including EPDM systems, TPO Systems, Metal Roofing Systems, BUR Tar & Gravel Systems, Asphalt Shingles, and PVC Systems. We also work with some of the leading manufacturers including Firestone, Carlisle, Duro-last, and Garland. Contact us today to learn more about what we can do for you!

Categorised in: Industrial Roofing, Roofing

This post was written by admin